Bangkok soy king: ‘Nowhere else is it done this way’

2022.07.21

Bangkok

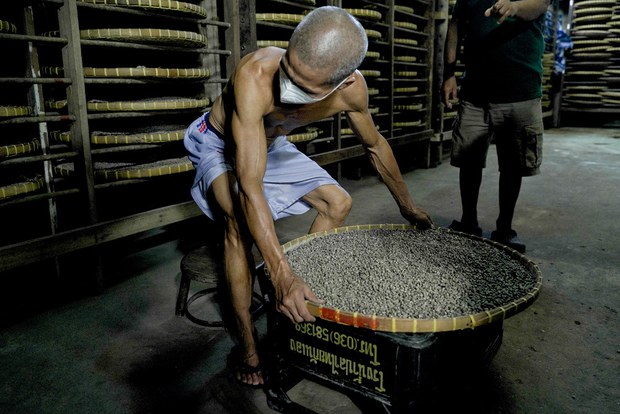

A century-old factory, which lies along a canal of the Chao Praya River in Bangkok’s historic Khlong Bang Luang neighborhood, offers visitors a window into the old-style production of soy sauce and an opportunity to taste products from a bygone era.

“Uncle” Somchai Kamolsakdavikun, 80, who owns the Hao Yong Seng factory, inherited it from his father. The old family recipe and production techniques, he boasts, are superior to modern-day techniques found at mass-production soy factories.

“I took over from my father – now it’s a 108-year-old business,” Somchai told BenarNews. “We ferment the soybean paste and leave it for a week. We use firewood to bring the sauce to a boil to sterilize it and good salt from Phetchaburi province [in central Thailand].”

“Nowhere else is it done this way because most have switched to industrial production, but the taste is not the same,” he said.

The building that houses the old factory sits on property where there used to be a palace.

Somchai’s father bought the land from a relative of King Rama VI (1881-1925). Somchai will pass on the family business to his son and grandchildren, hoping they’ll keep it going well into the future.

Somchai employs a six-step process. Select soybeans are boiled and then mixed with wheat flour to ferment. The beans are then marinated with sea salt, which brings out a sweet taste.

Step four requires boiling the fermented beans over firewood to bring out the natural flavor without adding sugar, coloring or other flavors. The last two steps require sun drying the sauce in large containers before fermenting for another four to five months.

Customers include traditional restaurants.

Somchai said his son, who is in his 50s, is poised to succeed him. Grandchildren who are studying food technology are expected to continue the family tradition.

“We survive. The factory can support itself because it’s small and doesn’t focus on making additional profits.”